Spiral Water is known for patented automated filtration that provides security for process systems that require fine filtration and are also affected by variable TSS and high solids loading.

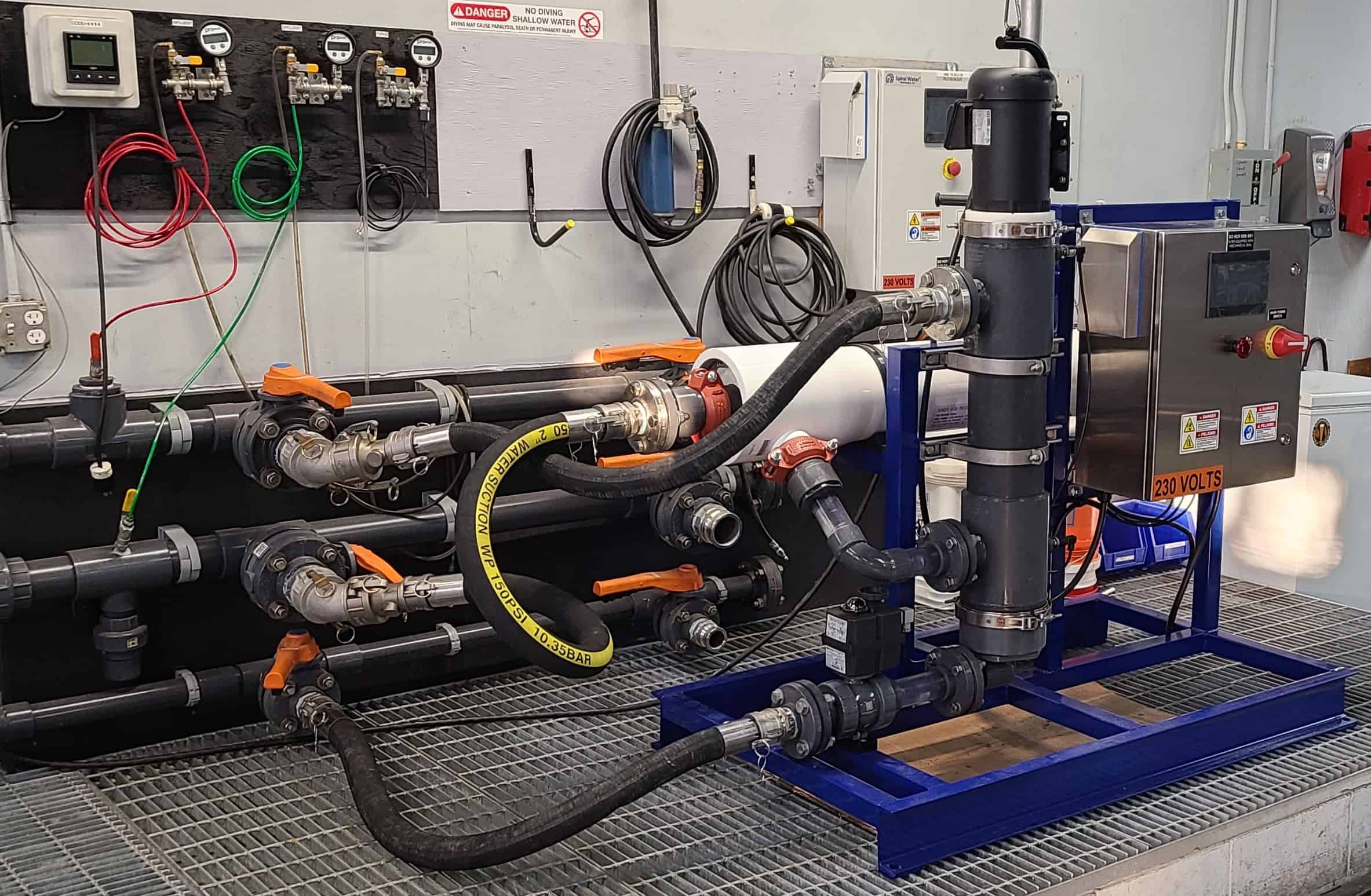

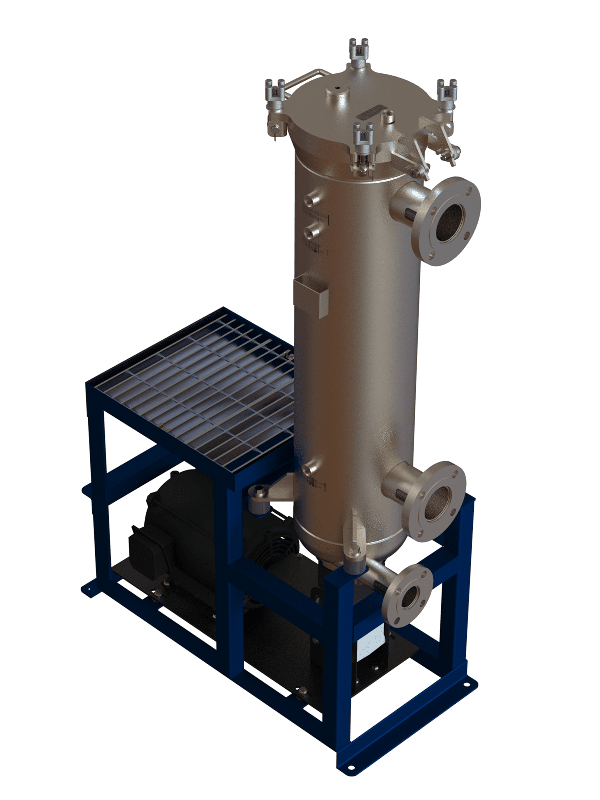

We’ve taken these systems one step further by coupling our 15µ Automatic Spiral Water Model 850 PVC Filter with Veolia’s 1µ Z.Plex Cartridge Filter. SWT’s Pre-Reverse Osmosis (R/O) Filtration System delivers a powerful one-two punch to help prevent clogging, enhance productivity, and reduce costs.

On their own, microfilter cartridges are prone to clogging if exposed to unexpected, high volumes of larger debris. However, including the 15µ Automatic Spiral Water Model 850 PVC Filter extends the life of the polishing 1µ Z.Plex Cartridge, which itself has 50x times the dirt holding capacity of a standard 40” 2.5 OD depth cartridge.

This new, extended long-life prefilter package automatically manages upset conditions as high as 2000 ppm without operator assistance. With a robust yet easy to use control interface, our system detects sudden upsets in process flow, and the filter expels the debris through its automated purge line. This enables the system to maintain continuous filtration of the influent stream without the need for operator intervention or cleaning.

Our Pre-R/O System offers a host of benefits. They include:

- Extended Filter Life: Our self-cleaning pre-filter removes larger particles before they reach the microfilter cartridge, thus extending the life of the more expensive microfilter cartridges.

- Improved Efficiency and Reduced Maintenance Costs: By preventing larger particles from entering the microfilter, our pre-filters maintain the microfilter’s effectiveness, ensuring that it can operate at its designed efficiency level. They also help reduce the frequency of filter replacements and maintenance – saving costs for materials and labor.

- Reduced Downtime: Our Model 850 filters eliminate the need for manual intervention, minimizing system downtime and ensuring continuous operation in applications where filtration is critical.

- Protection of Sensitive Equipment: Pre-filters play a vital role in preventing damage or contamination in applications where microfilters are used to protect sensitive equipment or processes.

- Improved Filtrate Quality: Pre-filtration significantly enhances the quality of the filtrate by removing large contaminants that could compromise the final product – essential in industries where product quality and purity are paramount.

- Environmental Considerations: Reducing the frequency of filter cartridge replacements saves costs while also reducing the environmental impact associated with the disposal of used cartridges.

Our next-generation automatic self-cleaning filters are widely used for industrial and organic wastewater treatment, pretreatment for microfiltration, ultrafiltration and reverse osmosis, water recycling and reuse across a variety of industries. Engineered with our patented high solids filtration and concentration technologies, they can be used as a prefilter, primary filter or for reclamation from existing filter backwash of centrifuge overflow. They are known for their ability to handle wastewater TSS removal and to process bulk solids removal up to 15,000 mg/l TSS (15% by volume), providing continuous 15 to 1500 micron filtration. Removal of TSS typically also removes a percentage of BOD and COD. In addition, our proprietary one-pass filtration process eliminates backwash of cross flow, thus conserving water, increasing uptime, and reducing CapEx.

To learn more, visit the product page, contact us by phone at (732) 629-7553 or email us at info@spiralwater.com.