MODEL 850 Solids Concentrating Automatic Filter

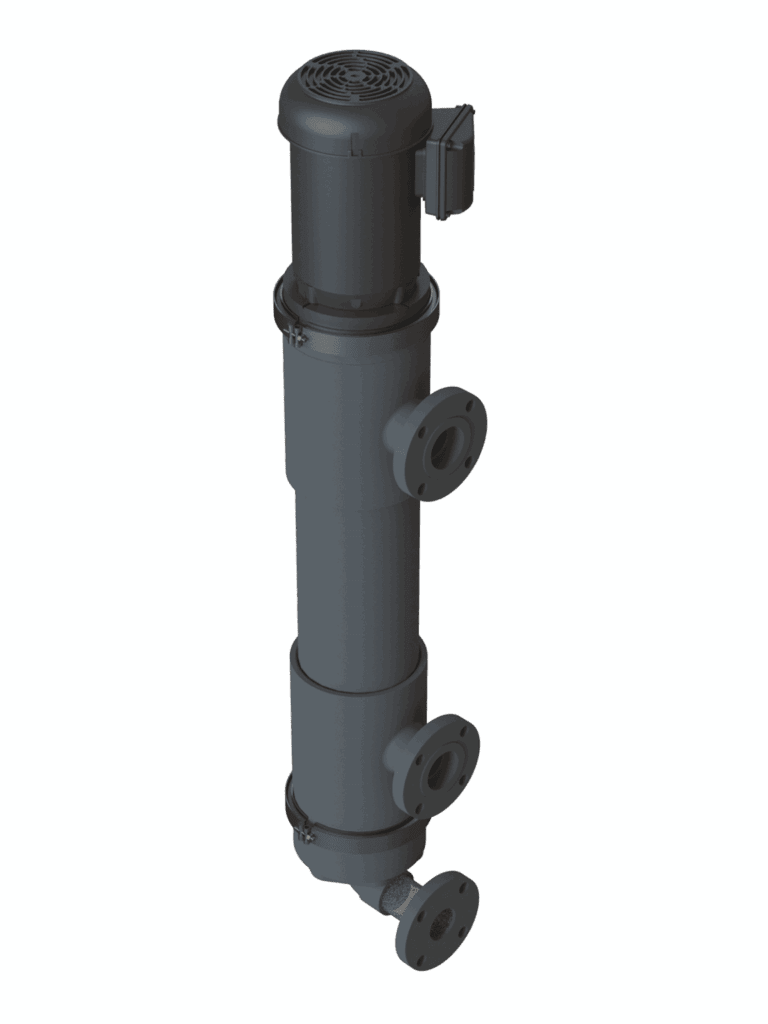

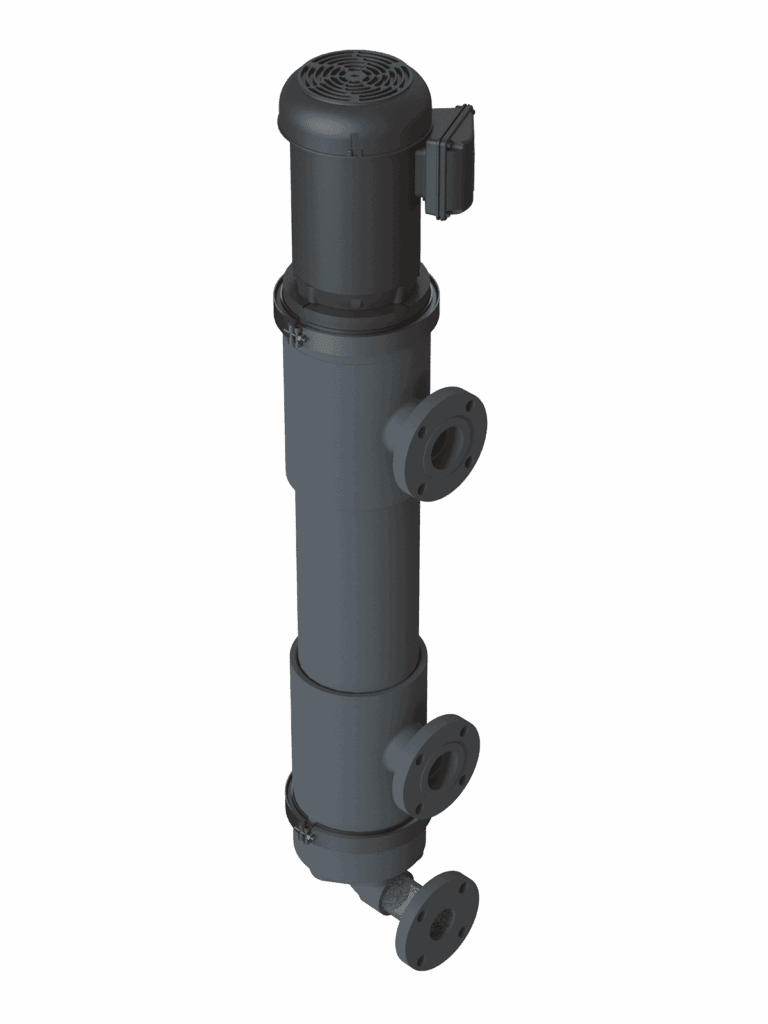

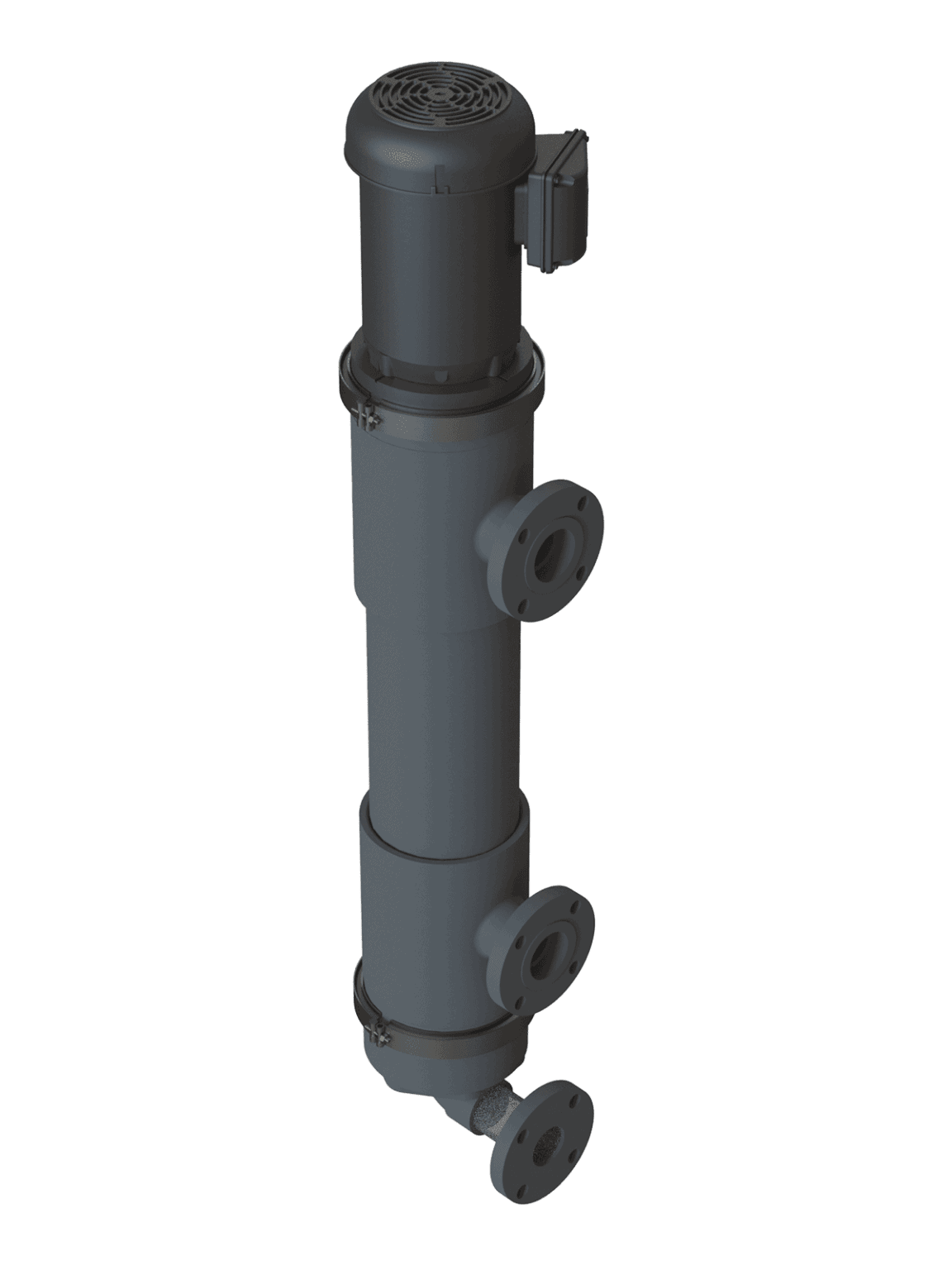

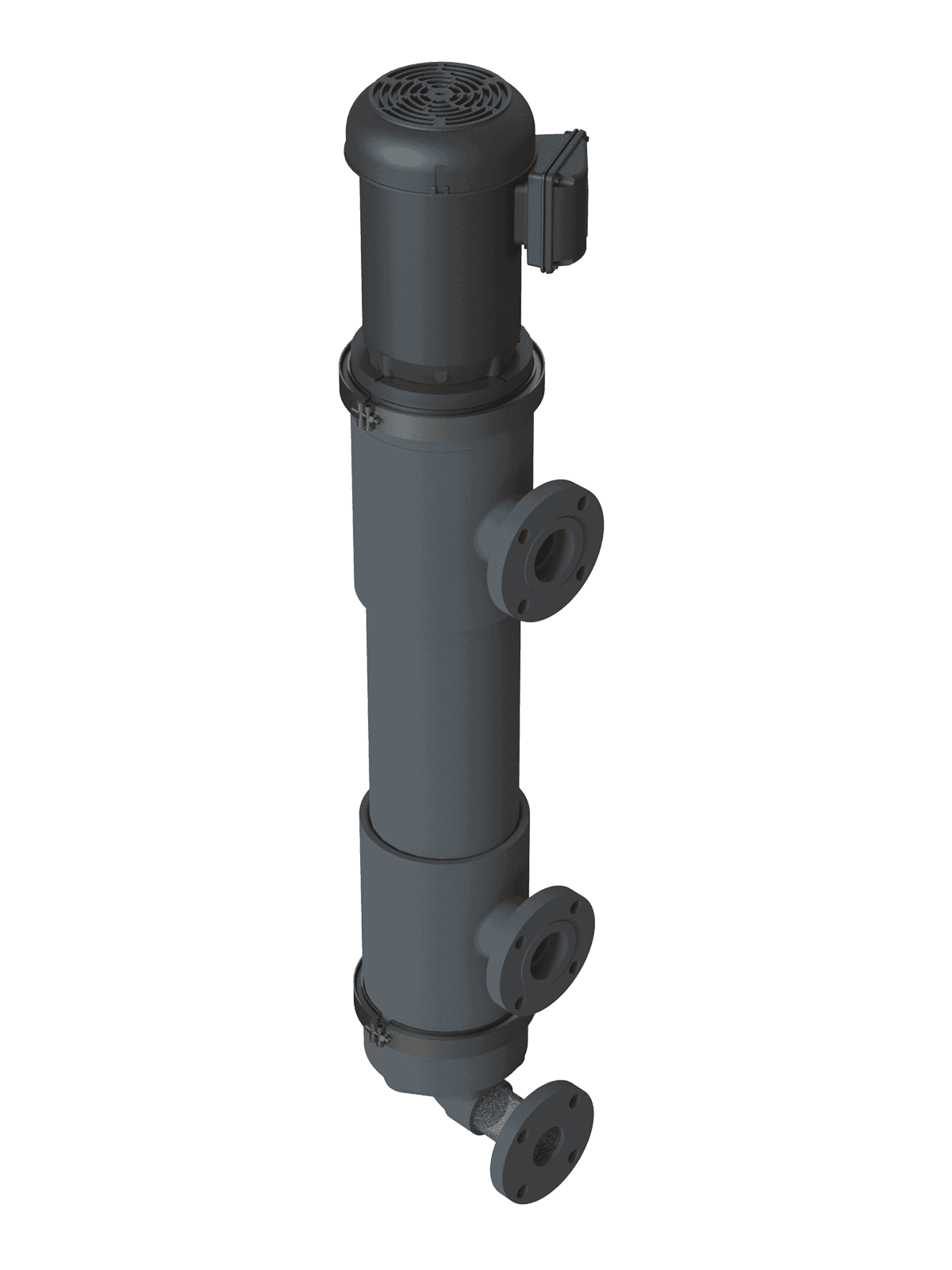

The SWT850 is the latest and most popular model in our 800 Series automatic self-cleaning filters. Designed to remove suspended solids (TSS) from high and variable total solids fluid streams, each filter unit contains a motor-driven, rotating spiral-shaped mechanical cleaning device that continuously cleans collected debris from inside the filter element. Solids are collected at the bottom of the filter housing to be expelled through an automatic purge valve or a continuous concentrate stream.

Unlike backwash filters, the SWT system does not require high pressure; it operates at system pressure of less than 20 psi and performs at very low differential pressure. No backwash, cross flow or booster pumps are required. The purge chamber can be configured to dump solids directly to waste or for removal and concentration of solids.

The latest evolution of our Series 800 filters, the SWT850 is designed to remove high total suspended solids (TSS) and reduces the rated flow by up to 50%.

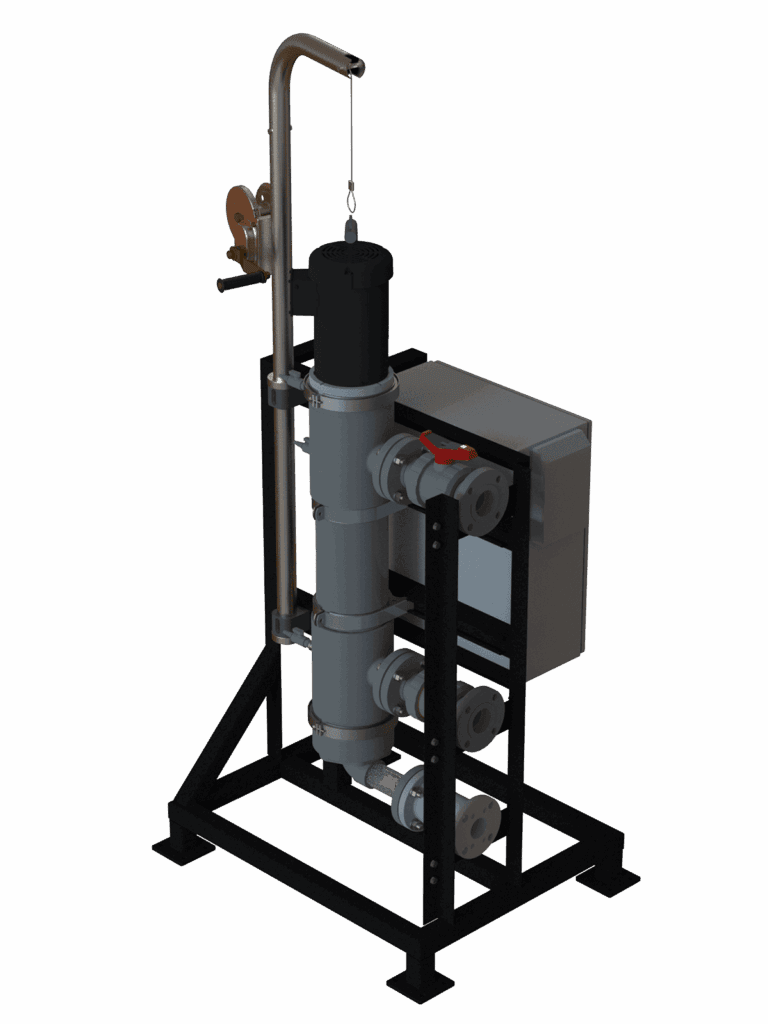

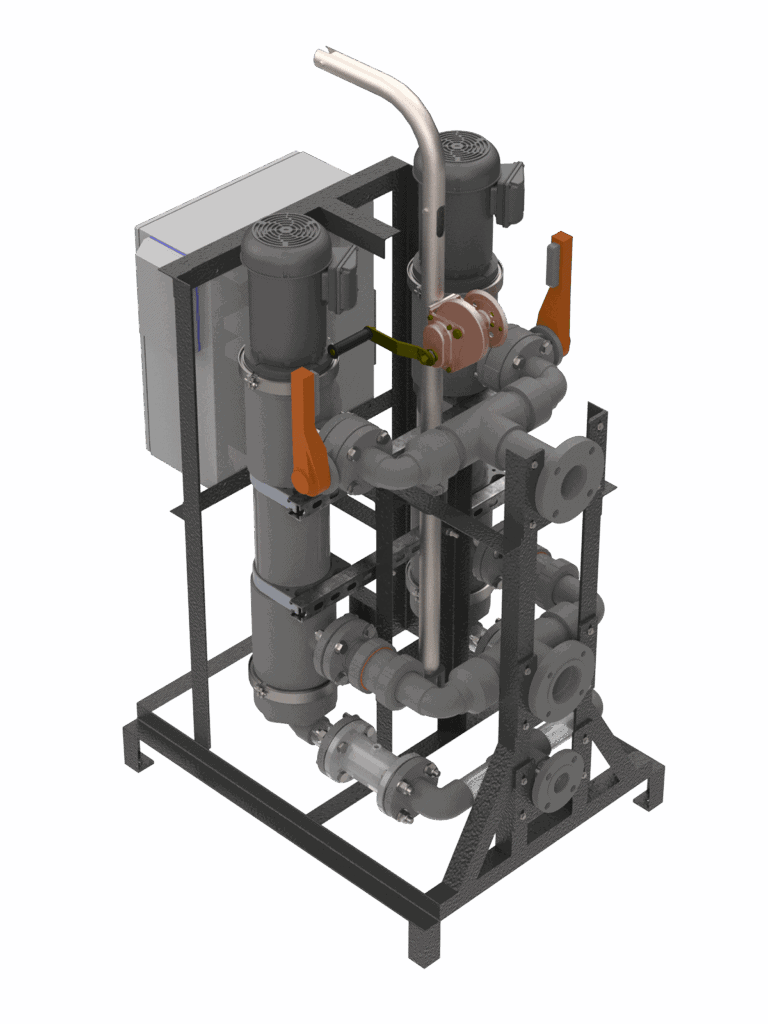

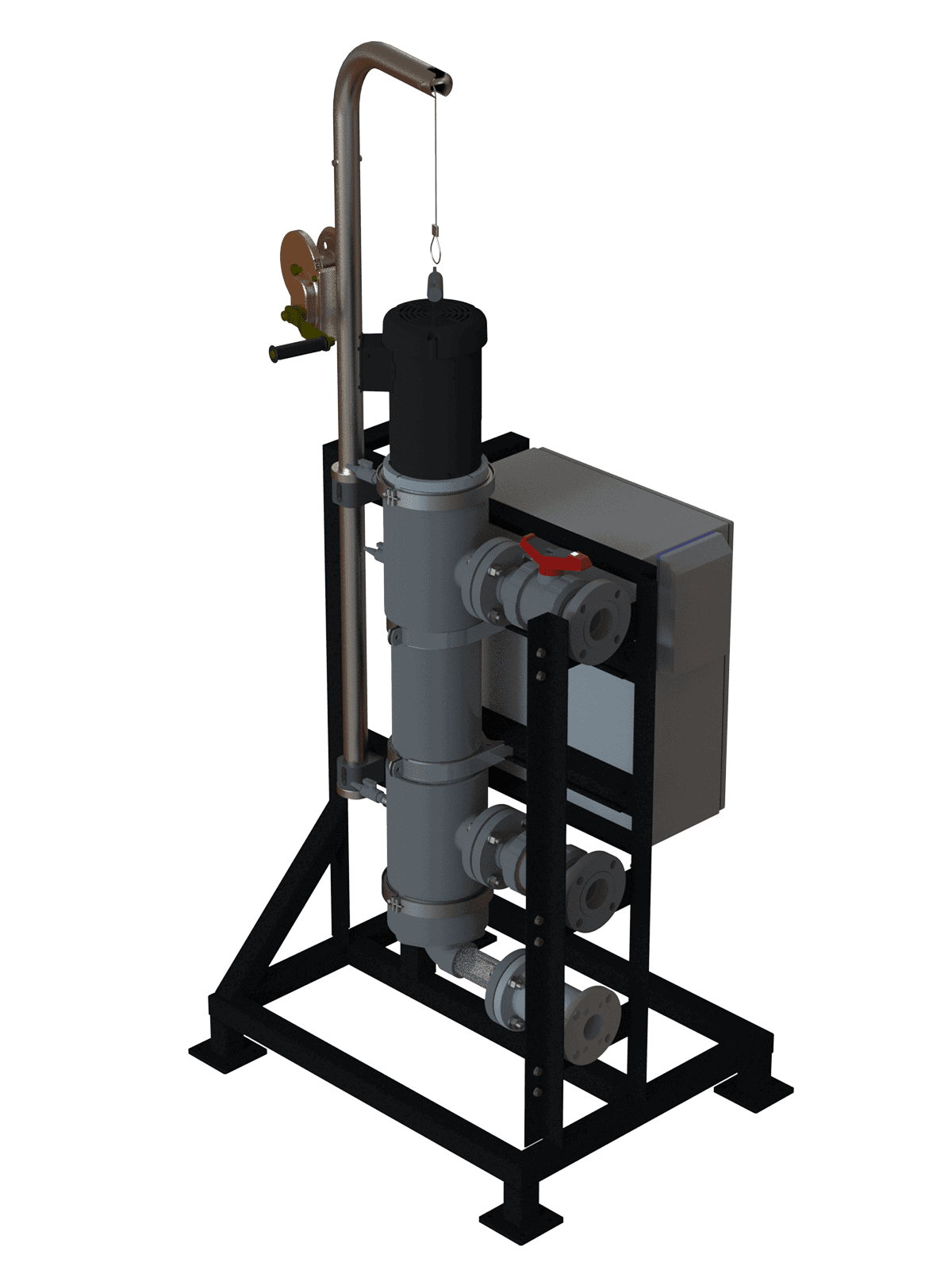

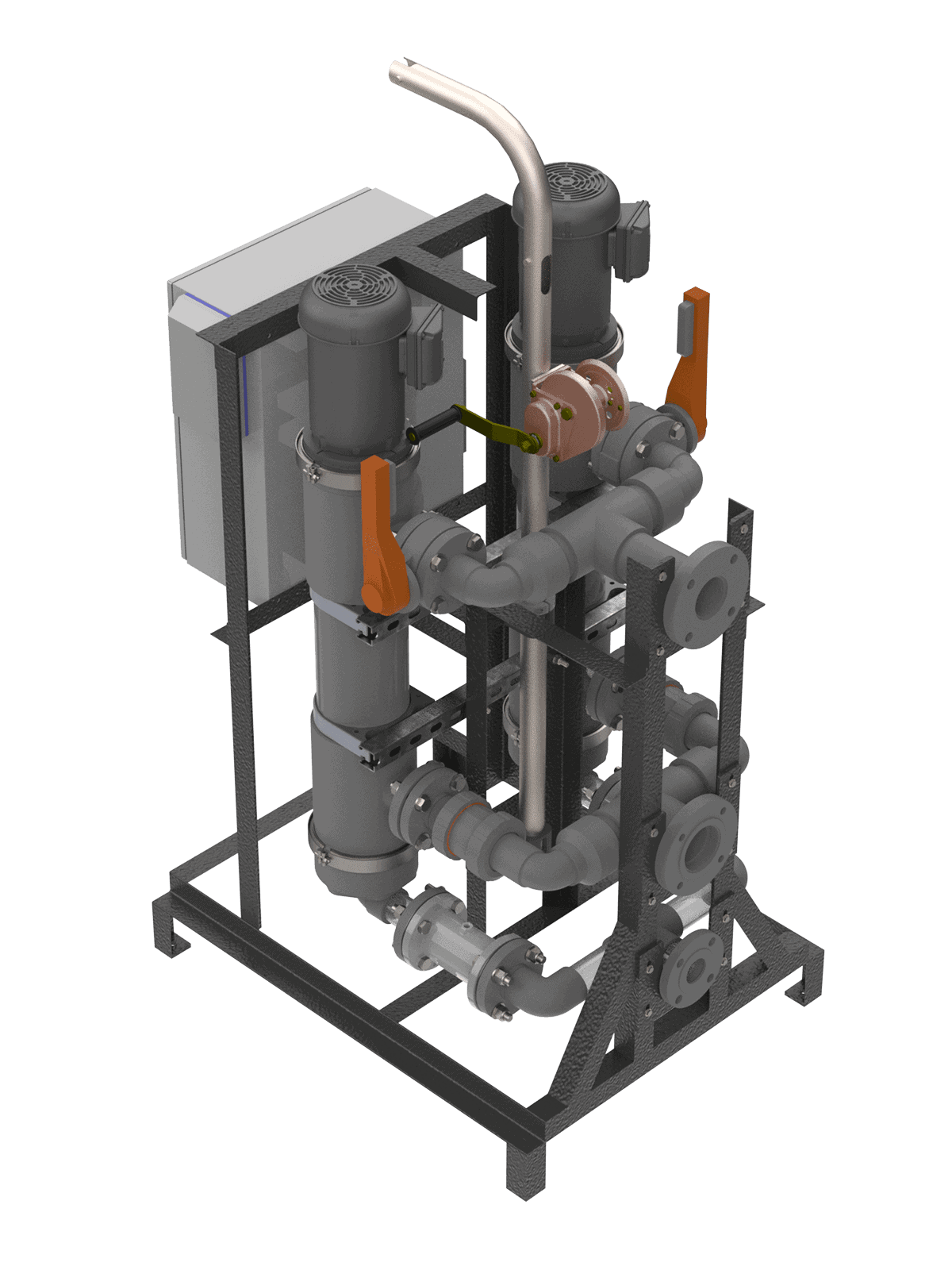

The filters are available in single (SWT850-OEM) or multiple (SWT850-DPX) filter configurations to satisfy higher customer application flow rates.

Making the Difference in Reducing Power Plant Downtime

A county utility in eastern Washington state operates one of the new generation micro-hydroelectric plants that deliver power generated by local rivers and streams. Designed to provide an energy efficient solution, the plant was experiencing an undesirable amount of downtime. Plant efficiency was affected by the high Total Suspended Solids (TSS) in the water source, which is subject to seasonal upset when weather and environmental conditions increase the turbidity of the local river.

The plant had relied on 200 micron bags to filter the water used to cool bearings and mechanical seals on the plant’s two system turbines. The bags filled to capacity on an irregular basis, depending on river conditions, requiring plant employees to travel to the unmanned facility to manually clean or replace the filters. Because clogged filters and bag replacement require operational stoppage, the plant had to keep employees on-call 24 hours a day to minimize hydroelectric downtime.

Spiral Water Technologies assessed the operation at the Washington facility. After making its recommendations, Spiral Water installed a 50 micron SWT 800 Series Filter inline prior to the plant’s mechanical seal water delivery.

The SWT is an automatic, self-cleaning water filter for ultra-high and variable Total Suspended Solids (TSS) of up to 25,000 ppm. The proprietary helical action of the Spiral Water Automatic Self Cleaning Filter is able to filter up to 100 times dirtier water and provide continuous 10 to 100 micron filtration with 90% less energy usage than traditional filtration systems.

The installation took approximately four hours and did not require removal of the existing bag filters or any system overhaul.

In addition to providing low micron filtration, the Spiral Water Automatic Filter system automatically collects, condenses and purges solids, eliminating the need to manually replace filter bags. This allowed the utility to improve employee efficiency and reduce costly operational downtime.

Contact us to learn more about Spiral Water’s 800 Series Filters and the SWT850, our latest model.

Model 850 Self-Cleaning Water Filters

The SWT850 is the latest and most popular model in our 800 Series automatic self-cleaning filters. Designed to remove suspended solids (TSS) from high and variable total solids fluid streams, each filter unit contains a motor-driven, rotating spiral-shaped mechanical cleaning device that continuously cleans collected debris from inside the filter element. Solids are collected at the bottom of the filter housing to be expelled through an automatic purge valve or a continuous concentrate stream.

Unlike backwash filters, the SWT system does not require high pressure; it operates at system pressure of less than 20 psi and performs at very low differential pressure. No backwash, cross flow or booster pumps are required. The purge chamber can be configured to dump solids directly to waste or for removal and concentration of solids.

The latest evolution of our Series 800 filters, the SWT850 is designed to remove high total suspended solids (TSS) and reduces the rated flow by up to 50%.

Available Options of Model 850 Self-Cleaning Filters

The filters are available in single (SWT850-OEM) or multiple (SWT850-DPX) filter configurations to satisfy higher customer application flow rates.

Benefits of Our Model 850 Automatic Self-Cleaning Filter

Spiral Water’s unique SWT850 water filtration unit is an automatic self-cleaning option for use in high-volume applications and wastewater with a high or variable level of solids. Each filtration unit includes a mechanical cleaning device with a spiral-shaped, continuously rotating element that filters the water passing through the unit. It can collect TSS particulates and collect debris within the bottom of the filter housing for easy, automated removal.

Key benefits of the SWT850 include:

Automatic self-cleaning processes: The unit will collect debris at the bottom of the filter and, once there is a sufficient pressure differential, automatically trigger a flushing sequence to clean the filter and remove the debris. The purging chamber can connect directly to waste systems for concentration and safe removal.

Performance without high-pressure levels: The SWT850 works with a system pressure of below 20 psi and low pressure differentials. Facilities don’t need to combine the filtration system with booster pumps, cross-flow pumps, or backwash prevention components.

Handles a high TSS level: This filtration unit can remove high levels of suspended solids from flows with high or varying levels of solid waste. It can also reduce the fluid flow rate by up to 50%.

Versatility: Our clients can select the right configuration based on their applications’ specific flow rate by using single (SWT850-OEM) filters or multiple (SWT850-DPX) filters.

Applications of Model 850 Automatic Self-Cleaning Filters

The SWT850 can assist with filtration in a wide array of commercial and industrial applications, especially when facilities rely on a continuous flow of water. Some key applications for our filters include:

- Industrial water filtration systems that rely on continuous cycles to extend the life of the equipment

- Irrigation systems that require ongoing fluid flow for nozzle protection

- Municipal water systems with membrane filtration components

Our filtration units are also used in the following applications:

Industrial Applications

Industrial systems rely on clean water. Not only is clean water essential for the production of goods themselves, but it also protects industrial equipment from exposure to scale building, clogs, and contamination or fouling. These incidents can lead to mechanical wear, interrupted maintenance cycles, and faster replacement demands. Through proactive water filtration with self-cleaning units, industrial facilities can protect their equipment and maintain more consistent uptime. Our filters remove particulates and are self-cleaning, eliminating the need for frequent manual maintenance.

Cooling Tower Filters

Process cooling systems house water that, left unfiltered, can collect particulates and debris. Filtration units can remove inorganic debris—dust, sand, and pipe scale—and organic debris—pollen and algae—that might otherwise collect in the water.

| How to Choose Between Spiral Water's Models 850 and 1000 Filters | |

|---|---|

| Model 850 All versions are single filter housing units (PVC, CPVC, 316 SSTL) | Model 1000 All versions are single filter housing units (T1000& H1000 304 SSTL standard) |

| Filter housing flow rate ranges from 10-80 gpm. | Filter housing flow rate ranges from 30-185 gpm. |

| Typically used for TSS of 2000 mg/l and under. | Typically used for higher TSS of 200 up to ~1.5% or 15,000 mg/l, but they can also be used effectively in low TSS applications as an insurance filter for variable upset conditions. |

| Screen micron size ranges from 15um to 1500um | Screen micron size ranges from 15um to 1500um. |

| Design Flow for plastic units should be less than 5 ft/second to minimize water hammer effects. | Flow velocities are similar to all metal pipes. |

| The higher the temperature above 100F, the more it derates the pressure rating in plastic filters. | Temperatures up to 190F do not reduce the MAWP |

Order Your Model 850 Automatic Self-Cleaning Filter From Spiral Water Today

High-performance filtration tools can optimize industrial and municipal water systems by removing contaminants and particles. Self-cleaning units can perform that function even better by automatically flushing buildup in the filter and ensuring ongoing filtration performance. Contact us today to learn more about our SWT850 self-cleaning filter or request a quote to start your order.