Series 1000 – Liquid/Solid Separator and Automatic Self-cleaning Filter

Our Series 1000 automatic self-cleaning filter is engineered for medium to high flow, high pressure, high temperature applications and liquid/solids separation. It is designed for industrial use to remove ultra-high and variable total suspended solids (TSS) from a fluid stream. Series 1000 filters are available in two models – the T1000 for industrial applications and the H1000 for clean processes where hygienic conditions are required. These models are made with stainless steel to ensure optimal durability.

Spiral Water’s Series 1000 automatic self-cleaning filters are specifically engineered to remove high total suspended solids/biochemical oxygen demand (TSS/BOD) from fluid streams. They can handle high TSS loading exceeding 500 ppm as well as remove bulk solids up to 15,000 mg/l all while providing continuous filtration for particle sizes between 15 and 1,500 microns. In a single pass, these filters are capable of filtering up to 50 times dirtier water with significantly less energy and a smaller footprint compared to large capital equipment.

Each filter unit contains a motor-driven, spiral-shaped brush that continuously cleans collected debris from inside the filter element. Solids collect at the bottom of the filter housing, to be expelled through an automatic purge valve or a continuous concentrate stream. The system does not require high pressures to operate and performs at very low differential pressure. No backwash, cross flow or booster pumps are required.

Systems are configured from single to multiple filter configurations to satisfy higher customer application flow rates. Depending on your particular needs, Series 1000 filters are available in various models for both industrial and food & beverage and other clean processes where hygienic conditions are required.

Contact Us

See the Spiral Water Model T1000 in Action

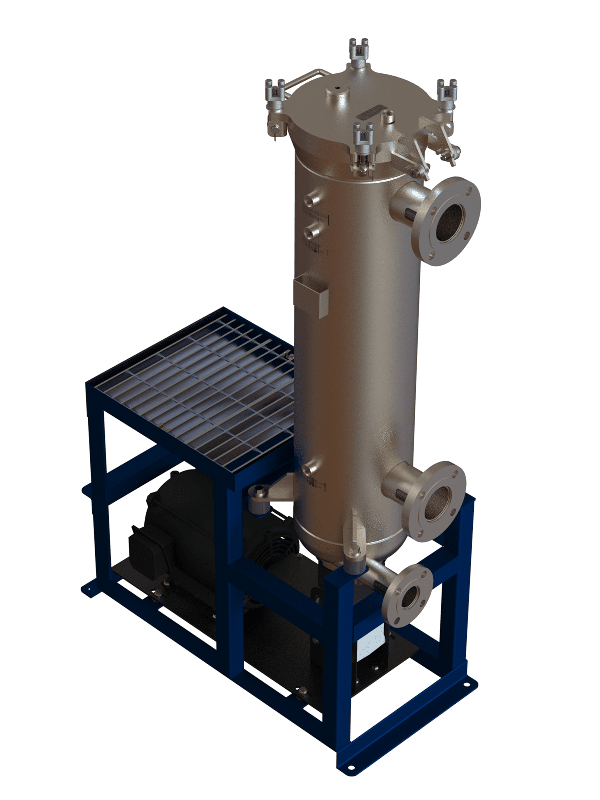

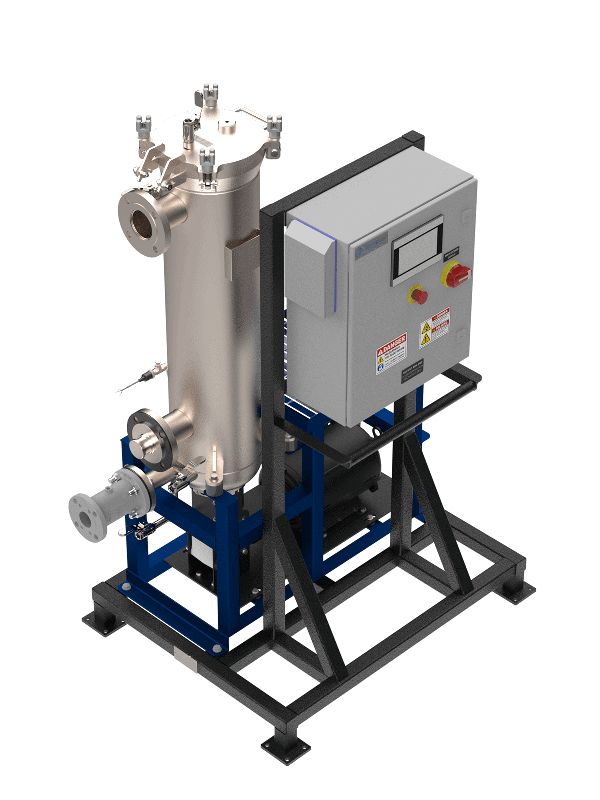

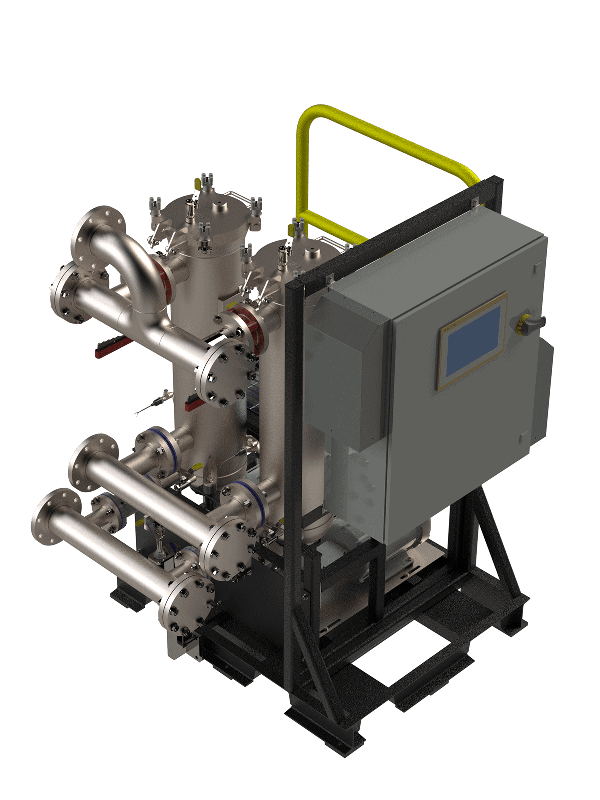

Our T-1000 filters are available in various configurations to meet your needs

T1000-OEM – Floor mounted single filter for use by OEMs and System Integrators (controls, sensors and valves by others)

T1000-SMS – Simplex panel – sensors and valves

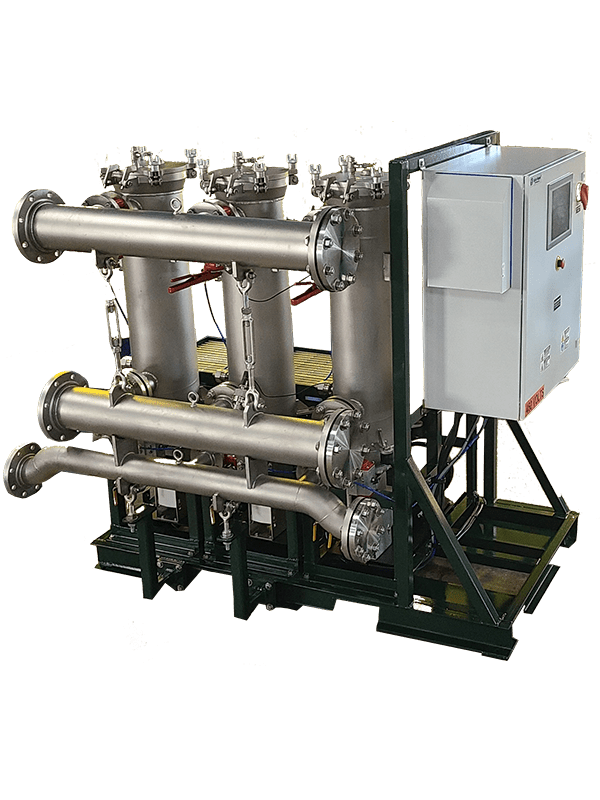

T1000-DPX – Duplex turnkey skid filter systems with 2 filters & mounted control panel – sensors and valves

T1000-TPX – Triplex turnkey skid filter system with 3 filters & mounted control panel – sensors and valves

T1000-QPX – Quadplex turnkey skid filter system with 4 filters & mounted control panel – sensors and valves

Spiral Water Series 1000 Success Story

A fruit and vegetable processor contacted Spiral Water to address two major issues: how to reduce the level of chemical consumption while also increasing their system’s processing uptime. Here’s how our Series H-1000 advanced automatic self-cleaning filters helped solve two problems at once.

A fruit and vegetable processor contacted Spiral Water to address two major issues: how to reduce the level of chemical consumption while also increasing their system’s processing uptime. Here’s how our Series H-1000 advanced automatic self-cleaning filters helped solve two problems at once.

The customer was using large amounts of chlorine and peracetic acid to control microbiological issues that might occur in their organic flumes for fruit and vegetable processing. The customer has a closed, continuously flowing system. Its several-hundred-gallon tank is filled with fresh water, which is treated with the chlorine and peracetic acid. Once the water hits a certain residual chlorine level (free chlorine and the total chlorine), processing can begin. The system is then brought up to speed and starts running, and the levels of chlorine are closely monitored. But as the residual chlorine decreased to a certain point, the customer would have to stop processing, because the system could not be re-dosed while it contained product. The organic load of the system was far too high for it to continuously process their product.

In addition, the temperature of the water must be maintained for the product to maintain its integrity. If it becomes too warm (which could happen during shutdown), the vegetables begin to soften and break down, significantly losing their shelf life. In this case, the solids that were being removed were small enough to get into their plate and frame chiller, therefore preventing it from operating at its optimum abilities. Since this was a closed system, the only solution was to shut it down two or three times a day to change out the water, add the requisite chemicals and restart the system.

Spiral Water installed a single Series H-1000 liquid/solid separator and automatic self-cleaning filter, which is engineered for medium to high flow, high pressure, high temperature applications and liquid/solids separation. It is designed for industrial use to remove ultra-high and variable total suspended solids (TSS) from a fluid stream. As a result, the Spiral Water team deduced that the customer was able to lower chemical usage by approximately 30% and reduce their chemical cost by about 60%.

Series 1000 Filter Systems From Spiral Water Technologies

Series 1000 automatic self-cleaning filters provide an ideal solution for a wide range of industrial and food & beverage applications, offering a reliable and efficient way of removing ultra-high and variable TSS from fluid streams. Our products can meet the needs of various industries, including wastewater treatment, breweries and distilleries, water reuse and recovery, and more. To learn more about how Spiral Water products can benefit your operations, contact us to speak with a technical representative today.