Products

- How Spiral Water's Mechanical Cleaning Filters Work

- Series 850: Solids Concentrating Automatic Filters

- Series 1000: Liquid/Solid Separator and Automatic Self-cleaning Filters

- SWT850 + Pre-R/O System: Extending Reverse Osmosis Efficiency

- HSWR System: Complete Water Recovery and Filtration Solutions

- Seamless System Integration for Industrial Water Treatment

- Smart Control Systems for Automated Filtration Management

- Industrial Applications: Where Spiral Water Filters Deliver Results

- Why Spiral Water Stands Apart from Other Self-Cleaning Filters

- Get a Custom Filtration Solution for Your Industrial Process Today!

How Spiral Water's Mechanical Cleaning Filters Work

Spiral Water Technologies offers self-cleaning industrial water filter products designed for high and variable TSS/BOD applications. Our filters provide pressurized separation from 10 micron to 4mm at system pressures from 150 to below 15 psi. Our advanced self-cleaning filters offer a cost-effective way to treat particulate-heavy fluid streams while also concentrating solids for low-volume discharge. These patented inline filters perform at very low differential pressure, without the need for cross flow, backwash, or booster pumps.

No Backwash, No Cross-Flow — Just Continuous Flow

Our filters operate differently from a standard backwash filter. They use a spiral-shaped, motor-driven brush to continuously clean debris from the filter element while a purge valve automatically removes any solids that have collected along the bottom of the filter housing. This unique design significantly reduces energy consumption and wastewater.

Smart Filtration That Adapts to Changing Solids Loading

Our self-cleaning filters feature automated controls that detect fluctuations in solids and adjust filtration accordingly. They’re designed for adaptability to ensure consistent performance even in high TSS environments, with no manual intervention necessary. Our products come in a variety of configurations to accommodate diverse process needs. Learn more about each of our self-cleaning industrial water filters below.

Series 850: Scalable Filtration for Industrial Processes

Series 850 and Series 1000 are industrial self-cleaning filters that have been engineered to remove high total suspended solids from fluid streams. Each option is recommended for specific environmental conditions.

Series 850: Compact, High-Solids Self-Cleaning Filter

Designed for low-pressure, high or variable TSS applications, our Model 850 features a compact design and mechanical cleaning mechanism. It is recommended for industries that deal with viscous products, like chemical or food processing. This filter comes in both single and multi-filter configurations for a variety of flow rate requirements.

Series 1000: Scalable Filtration for Industrial Processes

Series 1000: Robust, High-Flow Filtration for Heavy-Duty Use

Our Series 1000 filter is designed for medium to high flow, high-pressure applications. This filter is effective for filtering out high and variable TSS/BOD discharge from fluid streams and pressurized dewatering of sludge tanks (reducing hauling costs). Its robust design ensures reliable operation in demanding industrial environments as well as clean processes that require hygienic conditions. We offer both single and multi-filter options in various application-specific configurations.

SWT850 + Pre-R/O System: Extending Reverse Osmosis Efficiency

Spiral Water’s Pre-Reverse Osmosis System features a powerful combination of our Model 850 filter and a Veolia 1µ Z.Plex cartridge filter. Together, this long-life prefilter package manages demanding upset conditions without operator assistance.

Protecting RO Membranes from Premature Clogging

Integrating the SWT850 with reverse osmosis (RO) systems serves as a highly effective pre-filtration step. This combination removes high levels of suspended solids to protect RO membranes from clogging. The powerful results include:

- Continuous influent stream filtration

- Reduced maintenance

- Minimal cleaning costs

- Extended membrane lifespan

Self-Cleaning Pre-Filtration for Unexpected TSS Spikes

Our reliable SWT850 filter ensures continuous operation, even during sudden increases in TSS levels. When paired with a 1µ Z.Plex cartridge filter, it’s possible to maintain consistent water quality even under challenging conditions that require low turbidity.

HSWR System: Complete Water Recovery and Filtration Solutions

High solids water recovery (HSWR) systems from Spiral Water are powerful yet cost-efficient solutions for maximizing the recovery of industrial or wastewater. These turnkey solutions are configured according to the needs of each application.

Combining Filtration + Solids Concentration for Maximum Water Reuse

Our HSWR systems use innovative Spiral Water filter technology to effectively treat process water with TSS greater than 15,000 ppm. Water is filtered by a flow drum screen, where effluent is separated and then fed through an automatic filter. The filter reduces TSS by 50% and biological oxygen demand (BOD) by 30%, making it suitable for reuse.

Fully Customizable for Industrial and Commercial Applications

HSWR systems feature a versatile modular design that’s easily customizable to industry requirements. These solutions have been designed with flexibility in mind to accommodate diverse applications, ranging from wastewater treatment to industrial processes and more.

Seamless System Integration for Industrial Water Treatment

Many industrial processes require reliable access to clean, filtered water. In most applications, a filtration solution must not only be easy to install and maintain but also deliver reliable performance under rigorous conditions. Solutions from Spiral Water have been developed with these needs in mind.

Designed for Easy Installation and Retrofit Applications

Our filters are compact and modular for easy integration into a wide range of systems. Not only are they conveniently self-contained, but they require only a fraction of the footprint other filters demand. They can be easily retrofitted into most existing systems, with minimal downtime and installation costs.

Reliable Performance in Variable Water Conditions

Engineered to accommodate unpredictable TSS fluctuations, our filters ensure continuous operation without the need for manual intervention. In industries where water quality varies significantly, this reliability is essential.

Smart Control Systems for Automated Filtration Management

Spiral Water products feature proprietary solids sense technology to automatically initiate self-cleaning purges. A super-efficient, multi-second purge helps to concentrate solids while minimizing water usage.

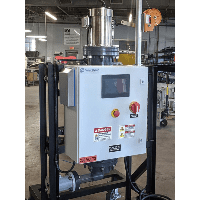

Customizable UL508A-Certified Control Panels

We offer UL508A-certified control panels to ensure compliance with even the most stringent safety standards. These panels are customizable to meet specific operational requirements.

Continuous Filtration with Minimal Operator Intervention

Automated controls allow our filters to quickly adapt to changing solids loading, greatly reducing the need to make manual adjustments. With automatic mechanical filtration in place, you’ll be able to reduce your maintenance costs and achieve more consistent filtration performance.

Industrial Applications: Where Spiral Water Filters Deliver Results

Solutions from Spiral Water are used throughout an extensive range of industrial sectors. Engineered with versatility and large-scale water needs in mind, our products achieve safe water for demanding applications within food and beverage, power generation, oil and gas, and much more.

Food and Beverage: Protecting Product Integrity

Achieving contaminant-free water is essential to the food and beverage industry. Our filters remove suspended solids from process water and effectively treat wastewater for safe and cost-effective disposal.

Power and Energy: Reducing Downtime in Critical Systems

Power plants and energy facilities require exceptional reliability from their systems. Spiral Water filters reduce downtime and maintenance costs by preventing fouling in cooling systems.

Oil and Gas: High-TSS Filtration for Produced Water and Frac Water

Managing high-TSS water can be a challenge within the oil and gas sector. Filters from Spiral Water handle these difficult conditions with ease, reducing an operation’s environmental impact and facilitating effective water reuse.

Why Spiral Water Stands Apart from Other Self-Cleaning Filters

Our high solids filtration systems use patented technology to outperform other self-cleaning filter designs. Continuous cleaning achieves powerful, low-maintenance results.

Outperforms Traditional Filters in High-TSS Environments

Spiral Water filters are uniquely engineered for high and variable TSS levels, vastly surpassing traditional self-cleaning filter capabilities. While a conventional filter can manage TSS concentrations up to 500 ppm, our technology processes TSS levels exceeding 15,000 mg/L. Our patented internal mechanical cleaning mechanism continuously cleans the filter screen without requiring cross-flow, backwash, high differential pressure, or downtime.

Efficient, Low-Maintenance, and Cost-Effective Filtration

Our unique filter design was designed with a focus on operational efficiency and cost-effectiveness. Automatic self-cleaning capabilities eliminate the need for disposable filters or manual cleaning, while the compact design facilitates easy integration into an existing system.

Get a Custom Filtration Solution for Your Industrial Process Today!

Spiral Water Technologies is your trusted partner for powerful self-cleaning industrial water filters. Our award-winning products are used throughout an extensive range of industrial sectors and are designed for fast and easy integration. If you’re interested in improving your filtration capabilities, contact us today. Our experts can create a custom solution tailored to your process needs.